Laboratory Flotation Cell distribution|flotation cell geometry experiments : manufacturing Bubble size distribution measured at concentrations exceeding the CCC values for three different frothers: (a) cumulative size distribution represented by an upper-limit . Resultado da As the Imperials, you will have a large amount of units and a star fortress that can obliterate planets. You must find and destroy the hidden rebel base to win. As the Rebels, you have a smaller amount of units, but they can be formidable in combat. Employ hit-and-run tactics and disrupt the Imperial agression.

{plog:ftitle_list}

Resultado da NSFW. Let it Loop. 787 5. u/Oscar996. • 2 mo. ago Vivi Winkler. 906 23. u/Single_Gemini. • 2 mo. ago She's got stars on her leggings and you can .

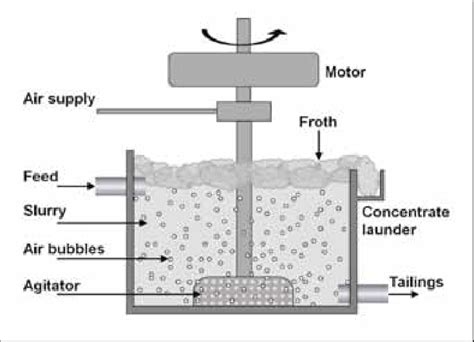

According to Amini et al. (2016) in a laboratory-scale flotation cell (5 litres, for. example), increasing the impeller speed leads to a decrease in bubble size up to a critical. speed, in which the impeller speed will no longer be able to reduce the bubble size.There are various designs of laboratory-scale flotation cells which can be used to perform the laboratory batch flotation tests. My preference is to use a bottom driven laboratory cell allowing . Bubble size distribution measured at concentrations exceeding the CCC values for three different frothers: (a) cumulative size distribution represented by an upper-limit . In this paper we show how the floatability distribution from measured laboratory batch cell test result can be estimated using Tikhonov regularisation (Tikhonov and Arsenin, .

This work makes use of a dual flotation–conductivity cell to assess the interaction between gas dispersion properties and flotation performance. Emphasis is placed .

determining the correct arrangement and size of the flotation cells based on batch and pilot test results (scaling-up) is extremely important for the overall results. Scale-up should also include . The distribution of air throughout the entire cell volume was at one time considered essential for cell effectiveness; however, in most modern flotation cells the .Gas dispersion in a laboratory Denver flotation cell was characterized by measuring the superficial gas velocity (J g), bubble size (db) and estimating the bubble surface area flux, Sb .

In a mechanical flotation cell, macro hydrodynamics is responsible for solids suspension and aggregates transport, and micro-turbulence plays an important role in the sub .

In this study, a laser diffraction technique (LDT) was used to measure a size distribution of bubbles generated in a two-phase system in a laboratory mechanical flotation cell.This 3 inch diameter Column Laboratory Flotation Cell is an ideal tool for evaluating the flotation characteristics of various mineral feeds. The laboratory cell includes the following features: electric, variable . The removal of any bubble distribution tube from the column simply requires closing the generator outlet valve, looseningFigure 23. Non-cumulative recovery over time for the 2-, 4- and 7.5 l cells. ... 48 Figure 24 Cumulative water recovery for the different impeller speeds after 7 minutes of flotation. .. 49 Tahvildarian et al. [23] employed ERT in investigating the mixing of micron-sized polymeric particles in a slurry reactor. Kourunen et al. [24] applied a 3D ERT to characterize gas hold-up distribution in a laboratory flotation cell. Other researchers [6,12,17,25–29] have analysed gas hold-up using ERT in a bubble column.

More recently, Guner et al. [15] investigated the residence time distribution in laboratory-scale ImhoflotTM V-03 and RefluxTM flotation cells (RFC-100), using KCl as a tracer for twophase systems . A dual flotation–conductivity laboratory flotation cell was implemented to study the effect of gas dispersion variables, including frother concentration, on the flotation performance. For a given flotation time, the cumulative copper recovery exhibited a fairly linear function of gas rate, and this relationship was modified by frother .Goodall, C.M., and O’Connor, C.T. (1989) Residence time distribution studies of the solid and liquid phases in a laboratory column flotation cell, in Proceedings Int. Coll. “Developments in Froth Flotation” (Gordon’s Bay, Cape Town), vol. 2, 15 pp. Google Scholar As seen, conventional flotation cells (i.e., MFC and column flotation cell (CFC)) cannot produce bubbles smaller than 0.5 mm with a reasonable concentration due to their natural bubble generation .

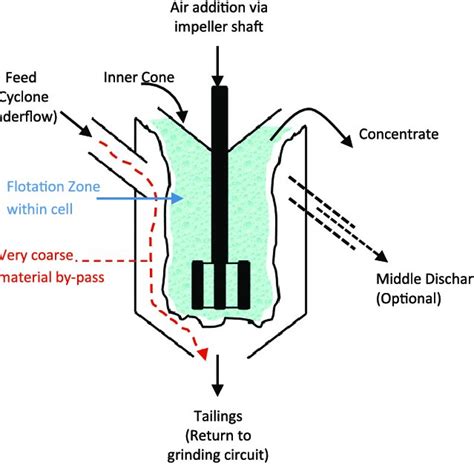

The present work investigates a comparative study between mechanical and ImhoflotTM cells on a mini-pilot scale and the applicability of one self-aspirated H-16 cell (hybrid ImhoflotTM cell) on an industrial scale on-site. The VM-04 cell (vertical feed to the separator vessel with 400 mm diameter) was fabricated, developed, and examined. The copper flotation .

flotation cell geometry experiments

experiments using flotation cells

The experiments were conducted in a 5.5 l laboratory-scale Denver flotation cell under semi-batch conditions (batch water, continuous air).Various frother concentrations (5, 20, 50 ppm) and impeller speeds (900–2300 rpm) were tested using water and frother, Dowfroth 250C (i.e., no solids are present).Suction airflow rate, created by the rotation of the impeller, .

The detailed principles, mechanism and operation of the flotation process are discussed focusing mainly on the hydrodynamic aspect which is required for the successful operation of the flotation cell. The kinetic modelling of flotation process has been reviewed in detail in three major flotation equipment namely mechanically agitated flotation .

The determination of the floatability distribution for froth flotation from laboratory batch cell tests is ill conditioned. Tikhonov regularisation with accuracy estimates, such as repeat tests for the recovery data, provides a way to produce solutions.

The determination of the floatability distribution for froth flotation from laboratory batch cell tests is ill conditioned. Tikhonov regularisation with accuracy estimates, such as repeat tests .

Bubble size as a function of impeller speed in a self-aeration laboratory flotation cell. James Finch. 2006, Minerals Engineering. See full PDF download . 507–513. Grau, R.A., Heiskanen, K., 2004. Bubble size distribution in laboratory scale flotation cells. In: Presentation at JKMRC International Student Conference, September 6–7 .There are various designs of laboratory-scale flotation cells which can be used to perform the laboratory batch flotation tests. My preference is to use a bottom driven laboratory cell allowing impeller speed and air rate adjustment, an example of which is shown in Figure 1. This type of cell, used with a fixed depthno flotation can occur. Contact between particles and bubbles can be accomplished in a flotation cell such as the one shown schematically in Figure 5. Figure 5: Simplified schematic of a conventional flotation cell. The rotor draws slurry through the stator and expels it to the sides, creating a suction that draws air down the shaft of the stator. Bubble size distribution (BSD) is a factor that is well known for influencing the performance of many industrial processes, such as froth flotation. . In a mechanical flotation cell, macro .

Work on flotation cells suggest that bubble size distributions can be reasonably well fit with lognormal distributions (Chen et al., 1998; Grau et al., 2005; Majumder et al., 2006) A lognormal probability density function is defined as P(x) 1 Let's define a set of n independent observations xn, (xnx), coming from a distribution with an unknown . The apparatus used was essentially a laboratory flotation cell, agitated by a Rushton turbine. The cell was modified to allow pre-formed clusters to rise out of a fluidized bed and into the path .

This paper presents the development of a small-scale (1 in.) laboratory flotation column with online measurement of bubble size. In contrast to the systems that use sampling-for-image techniques and have the viewing chamber located at the top of the flotation device, the system employed here measures the bubble size via image analysis using a bubble size .Semantic Scholar extracted view of "Studies on impeller type, impeller speed and air flow rate in an industrial scale flotation cell — Part 1: Effect on bubble size distribution" by B. Gorain et al. . An evaluation of a direct method of bubble size distribution measurement in a laboratory batch flotation cell. J. Tucker D. Deglon J .Laboratory mechanical flotation cells are extensively used in mineral processing for running batch flotation tests with a variety of purposes, for example assessing feed characteristics, determining

The performance of electroflotation (EF) is strongly influenced by the size of O2 and H2 bubbles. Therefore, in this study, the bubble sizes are measured in a lab-scale EF cell using a high-speed camera. The mean bubble size is found to vary in the range of 32.7–68.6 μm under different operating conditions. This study shows that the electrode material, current .Air bubble size distribution in a laboratory flotation cell was investigated by using of image analysis technology in this paper. Results showed that it was feasible to determine the air bubble size according to image analysis software. For a porous media-aerated flotation cell, bubble size was dependent on poles size of porous media. Request PDF | Application of three-dimensional electrical resistance tomography to characterize gas holdup distribution in laboratory flotation cell | Flotation is a separation process in which a .

Bank of flotation cells: schematic flotation process . the characterization of each cell’s volume and flotation efficiency is generally calculated from data gathered on a laboratory scale flotation using the same type of equipment for the same material mixture in question. . their distribution through the pulp being quite as even and . A dual flotation – conductivity laboratory flotation cell was implemented to study the effect of gas dispersion variables, including frother concentration, on the flotation performance.

web9 de ago. de 2023 · The Japanese word “bento” (お弁当, ōbento) translates to “lunch box.”. It is a single-portion meal that is typically packed in a box or container. Bento can be simple or elaborate, and it can be made with a variety of different foods. The word “bento” is derived from the Chinese word “bin,” which means “tray.”.

Laboratory Flotation Cell distribution|flotation cell geometry experiments